Showcasing engineering solutions, CAD designs, and physical product development.

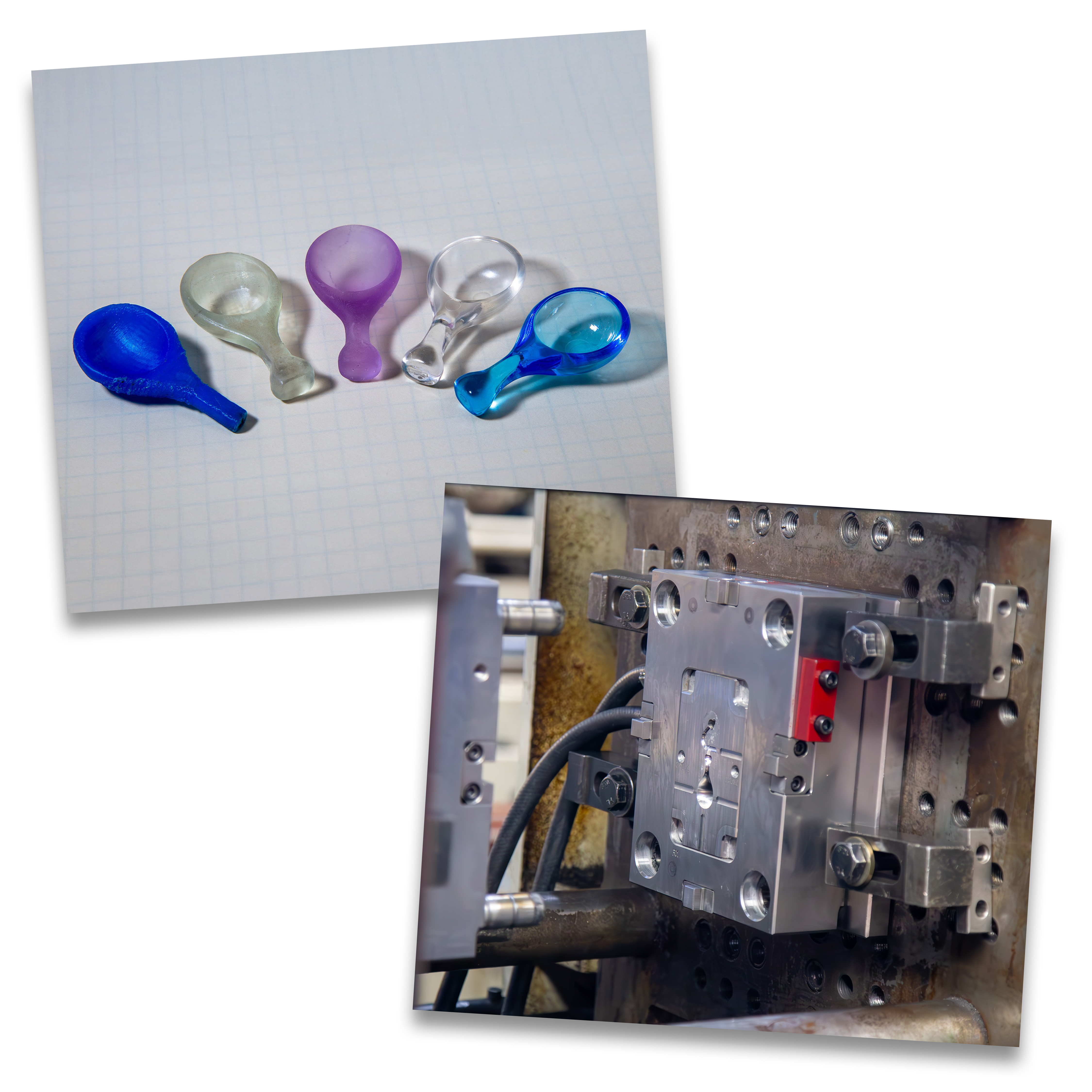

From rapid prototyping to production-ready parts, I bring designs to life using FDM and resin 3D printing. Additionally, my manufacturing experience spans from the machine shop to injection molding with both US and international manufacturers. I know how to optimize for cost, lead time, and material selection to transition smoothly from prototype to mass production.

For my senior design capstone, I helped design, manufacture, and build a digital microscope system for Seagate's clean room hard drive assembly line. This opto-mechanical system integrated precision optics, custom electronics, and mechanical assemblies into a production-ready inspection tool - delivering a fully functional system that met rigorous industrial requirements.

I design with usability and manufacturability in mind. Whether it's an all-in-one case for the Puffco Pivot, a can-operated bird feeder, or exploring new scoop designs in VR, I blend ergonomics, mechanism design, and practical constraints to create functional and beautiful products.